The

interoperable

UWB

standard.

What we do in omlox

TRUMPF is the market and technology leader in machine tools and lasers for industrial manufacturing. We offer the necessary tools to enable the smart factory capabilities of your company on every layer – from hardware to software and services. By analyzing improvement potentials, we learned, that the processes between the machines are the bottleneck for our customers, which is why we focus on intralogistics.

Location data is the enabler for a digital twin of your firm, which is one of the key instruments of industry 4.0 and improved intralogistics.

Our belief is, that only a standardized locating system can make the usage of location data widely available – also for small and medium sized companies.

This is why we are proud to be one of the founding members of omlox and will be driving the standard omlox in the future.

TRUMPF Tracking Technologies is your partner for open and flexible real-time locating solutions

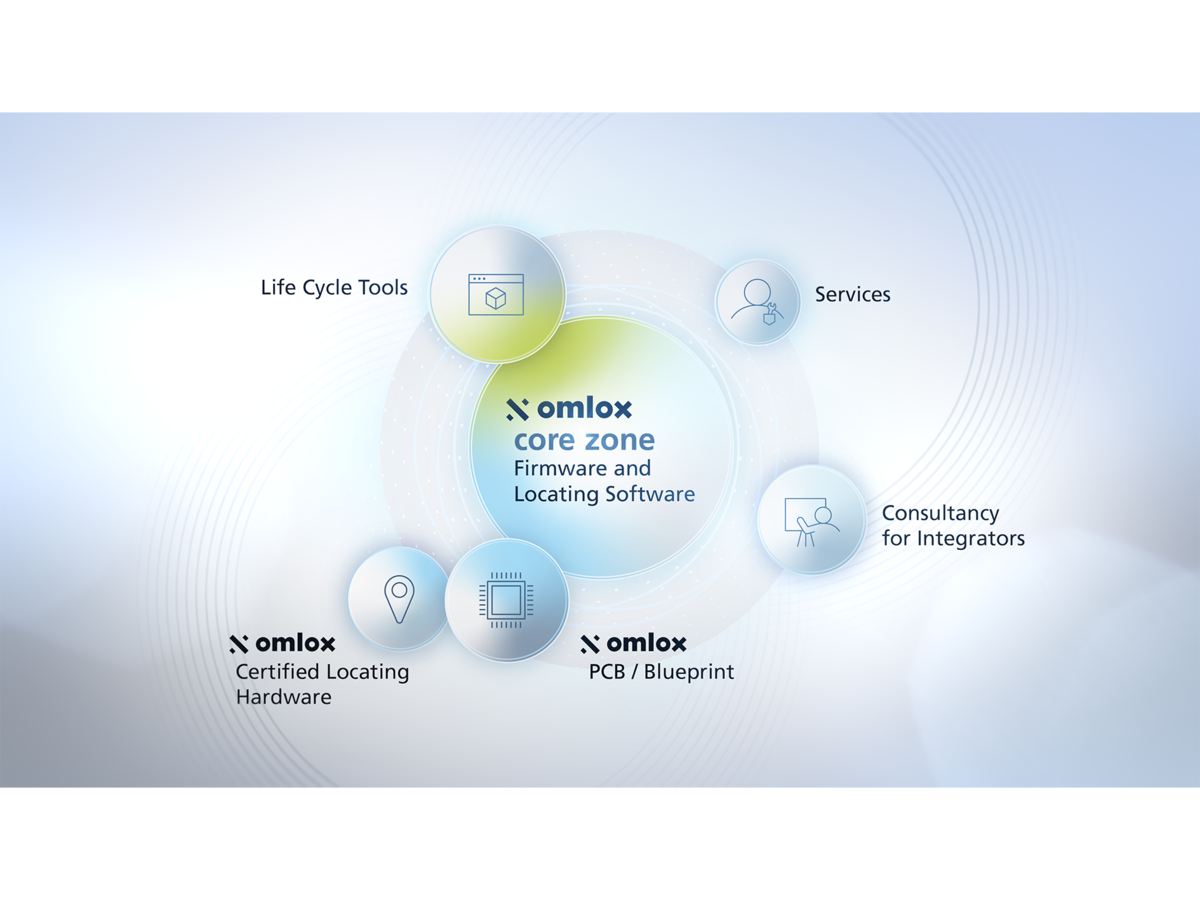

We are the first and leading enabler for system integrators and infrastructure providers, supporting them as they enhance their offering using flexible omlox-based real-time locating solutions. Our ultra-wideband-based RTLS delivers centimeter-level precision and is optimized for scalability, flexible deployment and robust operation in industry and beyond.

What we offer

How much time do your employees lose searching for orders and items on the shop floor? On average, human beings spend an entire year out of their lifetime searching for things. Sheet metal workers can now change this – with intelligent indoor localization for production areas.

Real Time Locating Systems (RTLS) enable real-time tracking of the position of objects and new applications such as automated guided vehicles (AGVs). However, positioning solutions are often offered proprietarily as a closed system and therefore cannot be used interoperably with other solutions.

TRUMPF is an infrastructure provider of the omlox core zone, a UWB based locating zone which provides interoperability between software and hardware components via the standardized air interface. TRUMPF enables integrators or infrastructure providers to offer flexible complete solutions for real-time location based on the world's first open location standard omlox. With our future-proof system infrastructure, we make simple and cost-effective localization within the omlox core zone possible.

Expertise in networking solutions

Benefit from our extensive experience, which we have already gained in our other business areas with Smart Factory and Smart Logistics solutions.

Tailor-made complete package

TRUMPF offers the infrastructure of the omlox core zone, including the corresponding software, hardware, services and consulting.

One exampe: Tool tracking

The TRUMPF TruTool TSC 100, used to clean slats on laser cutting machines, is a special power tool commonly used in industrial facilities. The built-in tracking capabilities of the tool allow for real time transparency and optimization. The tracking of the asset as well as recording of operating hours is essential for a well-functioning manufacturing environment. With the exact location information of the tools, search times can be reduced to zero and optimal maintenance intervals can be calculated with the help of usage times, derived from the location data. These functionalities make the TRUMPF TruTool TSC 100 a fully integrated power tool for highly automated industrial facilities.

cross-cooperation between Telekom & TRUMPF: 5G & omlox

Contact information

Our mission is to further develop and digitally connect production technology, to make it even more efficient, precise, and future-proof. In doing so, we want to make manufacturing and its upstream and downstream and supporting processes more efficient. This is how we build the industrial world of tomorrow. We are market and technology leaders in machine tools and lasers for industrial manufacturing, and work with our innovations in almost every sector. Our software solutions pave the way to the Smart Factory, allowing us to implement high-tech processes in industrial electronics.

Contact

Daniel Bossert

Chief Customer Officer

Email: daniel.bossert@trumpf.com

TRUMPF Tracking Technologies GmbH